Quadrature Output Dual Channel Speed Sensors – HD Series

The HD series quadrature output sensors are based on Hall Effect sensor technology, which can sense a change in target motion from true zero to 15 KHz. The HD series offers dual channel output and, where required, directional logic. The output frequency of HD sensors has a square pulse waveform (digital) that directly relates to the number of turbine blades, gear teeth, etc. that have been sensed. These pulses, in turn, can be correlated to determine flow rate, RPM, or velocity.

HD sensors are based on the H series which incorporate a magnet within the sensor, enabling them to sense ferrous metal as well as magnet targets. Maximum air gap sensing distances are typically 0.100″ and these sensors can be optimized to detect fine as well as large pitch targets.

General Operation

The HD series sensors consist of two hall-effect elements biased with a magnet to detect the change in magnetic field strength caused by the rotation of a ferrous target gear. When the target gear passes by sensor element A, the output switches from a logic 0 to a logic 1 at half the pitch (P/2) of the target gear. As the target gear continues, the output switches from a logic 1 to a logic 0 at the gear pitch (P).

Sensor element B is placed at a distance of one fourth of the pitch of the target gear (P/4) from element A. The output of element B is shifted by one forth (P/4) from the output of element A. In electrical terms, this creates a phase shift of 90°. When the gear turns in the counterclockwise direction, output A leads output B. When the gear turns in the clockwise direction, output A lags output B.

The descriptions above are only a theoretical ideal model to explain the fundamental operation of the HD series sensors. The realities of the physical world such as mechanical tolerances, magnetic field variations, and other physical phenomenon cause deviations from the ideal model. Visit our Practical Application Guide to learn more.

- Features & Specifications

- Standard Models

- 4.7 to 24 VDC regulated, 15 mA maximum @ no load

- Reverse polarity protected

- TTL/CMOS (Standard): fan-out of 5 TTL/CMOS loads

– VOL < 0.4V

– VOH > VOUT X (RLOAD / (RLOAD+1000) - Open Collector

- Supply tracking

-VOL < 0.4V

– VOH > (VSUPPLY – 0.2) X (RLOAD / (RLOAD+1000)

Push-Pull Type Output Options

- Push-Pull Fixed Voltage

– VOL < 0.4V @ 30mA

– VOH > VOUT – 0.4V @ -30mA - Push-Pull Supply Tracking

– VOL < 0.4V @ 30mA

– VOH > VSUP – 0.6V @ -30mA - Differential Push-Pull, Fixed or Supply Tracking

Airgap

Up to 0.100″ dependent on target geometry, magnet construction and sensor construction (for those based on the H series)

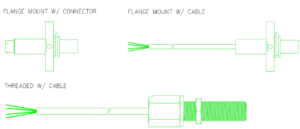

Interconnection Options

- Pigtail with wires or cable

- NPT threaded body with wire or cable pigtail for explosion proof environments

- Connector per customer specifications

Warranty

Unconditional one (1) year warranty if used within specifications

Physical Features

- Operating temperature:

-40°C to +125°C

Units that operate up to +150°C are also available - Storage temperature:

-40°C to +150°C - Body material: 300 series stainless steel

- Encapsulation: epoxy potting or hermetically sealed, welded construction

- High Shock and Vibration Resistance – contact factory for details

Orientation

- Alignment of the sensor to target rotation is required for optimal performance, ensuring proper orientation of the hall effect element to the magnetic field

- Our Quadrature sensors are aligned and tested with a 12 pitch gear. The alignment mark on the sensor housing is based upon the 12 pitch gear. In the event that a gear with a different pitch is used, the alignment mark should only be used as a starting point and the sensor should be rotated during installation while monitoring the output in order to obtain the proper Quadrature signal. If the proper alignment marking for use with a different pitch gear is desired, please contact the sales department with gear details prior to ordering.

CE compliant to EMC Directive 2004/108/EC for use in residential, commercial, light industrial and heavy industrial environments

| TYPE | OUTPUT | PART NUMBER | HOUSING | CONNECTION TYPE |

| Open Collector | Supply Tracking | HD-116 | Flange Mount | Connector |

| Open Collector | Supply Tracking | HD-117 | Flange Mount | Cable |

| Open Collector | Supply Tracking | HD-118 | 5/8-18 Thread | Cable |

| Open Collector | 5V | HD-119 | Flange Mount | Connector |

| Open Collector | 5V | HD-120 | Flange Mount | Cable |

| Open Collector | 5V | HD-121 | 5/8-18 Thread | Cable |

| Open Collector | Isolated, Supply Tracking | HD-122 | Flange Mount | Connector |

| Open Collector | Isolated, Supply Tracking | HD-123 | Flange Mount | Cable |

| Open Collector | Isolated, Supply Tracking | HD-124 | 5/8-18 Thread | Cable |

| Open Collector | Isolated, 5V | HD-125 | Flange Mount | Connector |

| Open Collector | Isolated, 5V | HD-126 | Flange Mount | Cable |

| Open Collector | Isolated, 5V | HD-127 | 5/8-18 Thread | Cable |

| Open Collector | Supply Tracking, Direction | HD-128 | Flange Mount | Connector |

| Open Collector | Supply Tracking, Direction | HD-129 | Flange Mount | Cable |

| Open Collector | Supply Tracking, Direction | HD-130 | 5/8-18 Thread | Cable |

| Open Collector | 5V, Direction | HD-131 | Flange Mount | Connector |

| Open Collector | 5V, Direction | HD-132 | Flange Mount | Cable |

| Open Collector | 5V, Direction | HD-133 | 5/8-18 Thread | Cable |

| Open Collector | None | HD-67 | Flange Mount | Connector |

| Open Collector | None | HD-134 | Flange Mount | Cable |

| Open Collector | None | HD-135 | 5/8-18 Thread | Cable |

| Open Collector | Direction | HD-136 | Flange Mount | Connector |

| Open Collector | Direction | HD-137 | Flange Mount | Cable |

| Open Collector | Direction | HD-138 | 5/8-18 Thread | Cable |

| Push/Pull | Supply Tracking | HD-139 | Flange Mount | Connector |

| Push/Pull | Supply Tracking | HD-140 | Flange Mount | Cable |

| Push/Pull | Supply Tracking | HD-141 | 5/8-18 Thread | Cable |

| Push/Pull | 5V | HD-142 | Flange Mount | Connector |

| Push/Pull | 5V | HD-143 | Flange Mount | Cable |

| Push/Pull | 5V | HD-144 | 5/8-18 Thread | Cable |

| Push/Pull | Differential, Supply Tracking | HD-145 | Flange Mount | Connector |

| Push/Pull | Differential, Supply Tracking | HD-146 | Flange Mount | Cable |

| Push/Pull | Differential, Supply Tracking | HD-147 | 5/8-18 Thread | Cable |

| Push/Pull | Differential, 5V | HD-148 | Flange Mount | Connector |

| Push/Pull | Differential, 5V | HD-149 | Flange Mount | Cable |

| Push/Pull | Differential, 5V | HD-150 | 5/8-18 Thread | Cable |

| Push/Pull | Supply Tracking, Direction | HD-151 | Flange Mount | Connector |

| Push/Pull | Supply Tracking, Direction | HD-152 | Flange Mount | Cable |

| Push/Pull | Supply Tracking, Direction | HD-153 | 5/8-18 Thread | Cable |

| Push/Pull | 5V, Direction | HD-154 | Flange Mount | Connector |

| Push/Pull | 5V, Direction | HD-155 | Flange Mount | Cable |

| Push/Pull | 5V, Direction | HD-156 | 5/8-18 Thread | Cable |

| Push/Pull | Isolated, Supply Tracking | HD-157 | Flange Mount | Connector |

| Push/Pull | Isolated, Supply Tracking | HD-158 | Flange Mount | Cable |

| Push/Pull | Isolated, Supply Tracking | HD-159 | 5/8-18 Thread | Cable |

NOTES:

Dimensions in inches

Specifications +/-10%

Mounting threads UNF-2A